- ISHIKAWA DIAGRAM 6M SAMPLE HOW TO

- ISHIKAWA DIAGRAM 6M SAMPLE PDF

- ISHIKAWA DIAGRAM 6M SAMPLE GENERATOR

- ISHIKAWA DIAGRAM 6M SAMPLE PROFESSIONAL

How to do capacity analysis for manufacturing 2.8k views.Overall Equipment Effectiveness (OEE) 2.9k views.

ISHIKAWA DIAGRAM 6M SAMPLE GENERATOR

ISHIKAWA DIAGRAM 6M SAMPLE PDF

8D report preparation in Downloadable PPT, Excel and PDF templates| with Example | 6.3k views.How to calculate No of workstations from Takt time and Cycle Time 6.7k views.How to calculate manpower for Preventive Maintenance 7.1k views.Manpower calculation using takt time 9.2k views.Takt Time, Cycle Time, Throughput time,Lead Time – The difference 10.4k views.

ISHIKAWA DIAGRAM 6M SAMPLE PROFESSIONAL

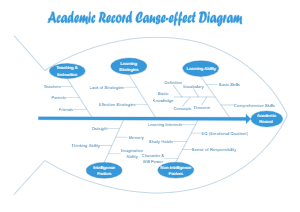

Online exam for testing skills of an Industrial Engineering professional 10.5k views.Kaizen Events: How and when to use them 11.3k views.How To Calculate Manpower Efficiency 11.6k views.Complete Data Science Roadmap – With resources 12.1k views.Load Chart – For Scheduling, Monitoring and Tracing of production 12.6k views.How to calculate headcount required in Excel 18.7k views.CLIT sheet and Autonomous Maintenance 24.7k views.Line Balancing – How to do it 25.1k views.Manpower Requirement Calculation 45.2k views.Value Stream Mapping Symbols Popular posts As the diagram gets developed, team needs to focus on the area where the idea are less and needs more focus.Prioritize the most likely WHYs for further investigation. Each WHY may have multiple WHYs which are worth considering. Ask: Why (Also known as 5Whys): The simple way to get down to the deeper cause is to ask the question WHY? Team needs to keep asking the “WHY” until you get something that feels like the root cause of the problem.If you have a contributing factor that fits into more than one category, place it in each location, and see whether, in the end, considering that factor from multiple points of view has made a difference. Team needs to identify the factors which are contributing the possible causes of that specific problem. In each category, one can find the lines as shown in the figure. The diagram will look like a fish bone now after all the categories are identified and attached to the potential problems. Contributing factors/Sub-categories: After brainstorming possible causes, attach each causes with the ribs of the fishbone diagram.He was born in Japan on July 13 th 1915 and was popular for the development of quality initiatives specifically, Quality circle. What is another name for a fishbone diagramįishbone Diagram is also known as the following įishbone diagram was invented in the year 1960s by Kaoru Ishikawa, one of the most renowned quality management innovationists. What is another name for a fishbone diagram.We will discuss following topics in this article. It gives privilege to the project teams by visualizing the diagram to identify the root cause of any problem, prioritize them and solve the problems simultaneously. MIXED MODEL PRODUCTION MANPOWER CALCULATORįishbone Diagram is the visualization tool and principal part of Quality tools.RANDOM TIME GENERATOR FOR WORK SAMPLING.

0 kommentar(er)

0 kommentar(er)